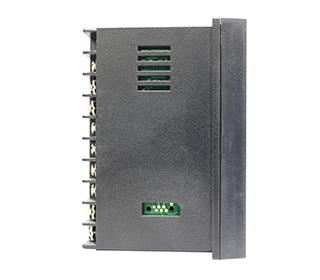

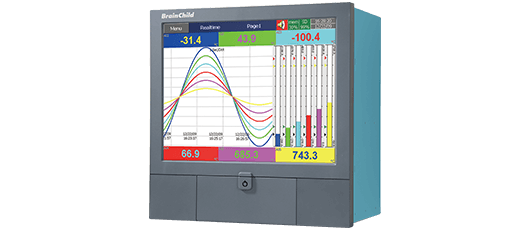

Ramp Soak Controllers

The Fuzzy Logic plus PID microprocessor-based profiling controller with many segments of ramp and dwell, incorporate two bright, easy to read 4-digit LED displays, indicating process value and set point value. The Fuzzy Logic technology enables a process to reach a predetermined set point in the shortest time, with the minimum of overshoot during power-up or external load disturbance.

- Total 9 profiles, a profile with 16, 32 or 64 segments at most

- Each segment to be configured as a ramp or dwell(soak)

- Fast A-D sampling rate (5 times/s)

- After an event the process goes to run, hold, abort, manual, failure transfer, off mode, next segment or select the second PID values

- High accuracy of 18-bit A to D input, and 15-bit D to A output

- The fast sample rate of 200 msec

- Fuzzy control to reach set point at the least overshooting ans less time

- Up to three relays are configurable for event output

- Analog retransmission of process value & set point value

- Optional RS-485 or 232 communications

- Programmable port for easy configuration or calibration

- Lockout protection for security requirement

- Bumpless transfer of safely control while sensor breaks

- Digital filter to improve the stability of process value

- SEL function for easy operation

| Power |

|---|

| 90 - 250 VAC, 47 - 63 Hz, 12VA, 5W maximum |

| 11 - 26 VAC / VDC, SELV, Limited Energy, 12VA, 5W maximum |

| Signal Input | |

|---|---|

| Resolution | 18 bits |

| Sampling Rate | 5 times / second |

| Maximum Rating | -2 VDC minimum, 12 VDC maximum( 1 minute for mA input ) |

| Temperature Effect | ±1.5 uV/ °C for all inputs except mA input ±3.0 uV/ °C for mA input |

| Sensor Lead Resistance Effect | T/C: 0.2uV/ohm 3-wire RTD: 2.6 °C/ohm of resistance difference of two leads 2-wire RTD: 2.6 °C/ohm of resistance sum of two leads |

| Burn-out Current | 200nA |

| Common Mode Rejection Ratio ( CMRR ) | 120dB |

| Normal Mode Rejection Ratio ( NMRR ) | 55dB |

| Sensor Break Detection | Sensor open for TC, RTD and mV inputs, Sensor short for RTD input, below 1 mA for 4-20 mA input, below 0.25V for 1 - 5 V input, unavailable for other inputs. |

| Sensor Break Responding Time | Within 4 seconds for TC, RTD and mV inputs, 0.1 second for 4-20 mA and 1 - 5 V inputs. |

| Input | |||

|---|---|---|---|

| Type | Range | Accuracy@ 25 °C | Input Impedance |

| J | -120 ~ 1000 °C (-184 ~ 1832 °F) | ±2 °C | 2.2MΩ |

| K | -200 ~ 1370 °C (-328 ~ 2498°F) | ±2 °C | 2.2MΩ |

| T | -250 ~ 400°C (-418 ~ 752°F) | ±2 °C | 2.2MΩ |

| E | -100 ~ 900 °C (-148 ~ 1652 °F) | ±2 °C | 2.2MΩ |

| B | 0 ~ 1800 °C (32 ~ 3272 °F) | ±2 °C (200°C - 1800°C) | 2.2MΩ |

| R | 0 ~ 1767.8 °C (32 ~ 3214 °F) | ±2 °C | 2.2MΩ |

| S | 0 ~ 1767.8 °C (32 ~ 3214 °F) | ±2 °C | 2.2MΩ |

| N | -250 ~ 1300 °C (-418 ~ 2372 °F) | ±2 °C | 2.2MΩ |

| L | -200 ~ 900 °C (-328 ~ 1652 °F) | ±2 °C | 2.2MΩ |

| PT100 (DIN) | -210 ~ 700 °C (-346 ~ 1292 °F) | ±0.4°C | 1.3KΩ |

| PT100 (JIS) | -200 ~ 600 °C (-328 ~ 1112 °F) | ±0.4°C | 1.3KΩ |

| mV | -8 ~ 70mV | ±0.05% | 2.2MΩ |

| mA | -3 ~ 27mA | ±0.05% | 70.5Ω |

| V | -1.3 ~ 11.5V | ±0.05% | 650KΩ |

| Output 1 / Output 2 | |

|---|---|

| Relay Rating | 2A/240 VAC, life cycles 200,000 for resistive load |

| Pulsed Voltage | Source Voltage 5V, current limiting resistance 66Ω . |

| Output | |||

|---|---|---|---|

| Type | Zero Tolerance | Span Tolerance | Load Capacity |

| 4-20 mA | 3.6-4 mA | 20-21 mA | 500Ω max. |

| 0-20 mA | 0 mA | 20-21 mA | 500Ω max. |

| 0-5 V | 0 V | 5-5.25 V | 10KΩ min. |

| 1-5 V | 0.9-1 V | 5-5.25 V | 10KΩ min. |

| 0-10 V | 0 V | 10-10.5 V | 10KΩ min. |

| Linear Output | |

|---|---|

| Resolution | 15 bits |

| Output Regulation | 0.02 % for full load change |

| Output Settling Time | 0.1 sec. ( stable to 99.9 % ) |

| Isolation Breakdown Voltage | 1000 VAC |

| Temperature Effect | ±0.01 % of SPAN / °C |

| Triac ( SSR ) Output | |

|---|---|

| Rating | 1A / 240 VAC |

| Inrush Current | 20A for a cycle |

| Min. Load Current | 50 mA rms |

| Max. Off-state Leakage | 3 mA rms |

| Max. On-state Voltage | 1.5V rms |

| Insulation Resistance | 1000 Mohms min. at 500 VDC |

| Dielectric Strength | 2500 VAC for 1 minute |

| Type | Tolerance | Max. Output Current | Ripple Voltage | Isolation Brrifer |

| 20V | ±1V | 25mA | 0.2Vp-p | 500VAC |

| 12V | ±0.6V | 40mA | 0.1Vp-p | 500VAC |

| 5V | ±0.25V | 80mA | 0.05Vp-p | 500VAC |

| Alarm | |

|---|---|

| Alarm Relay | Form C,Max. rating 2A/240VAC, life cycles 200,000 for resistive load. |

| Alarm Functions | Dwell timer, Deviation High / Low Alarm, Deviation Band High / Low Alarm PV High / Low Alarm |

| Alarm Mode | Normal, Latching, Hold, Latching / Hold. |

| Dwell Timer | 0.1 - 4553.6 minutes |

| Data Communication | |

|---|---|

| Interface | RS-232 ( 1 unit ), RS-485 ( up to 247 units ) |

| Protocol | Modbus Protocol RTU mode |

| Address | 1 - 247 |

| Baud Rate | 2.4 ~ 38.4 Kbits/秒 |

| Parity Bit | None, Even or Odd |

| Stop Bit | 1 or 2 bits |

| Communication Buffer | 64 bytes |

| Analog Retransmission | |

|---|---|

| Output Signal | 4-20 mA, 0-20 mA, 0-1V, 0-5V, 1-5V, 0-10V |

| Resolution | 15 bits |

| Accuracy | ±0.05 % of span ±0.0025 %/ °C |

| Load Resistance | 0 - 500 ohms ( for current output ),10 K ohm minimum ( for voltage output ) |

| Output Regulation | 0.01 % for full load change |

| Output Settling Time | 0.1 sec. (stable to 99.9 % ) |

| Isolation Breakdown Voltage | 1000 VAC min. |

| Integral Linearity Error | ±0.005 % of span |

| Temperature Effect | ±0.0025 % of span/ °C |

| Saturation Low | 0 mA ( or 0V ) |

| Saturation High | 22.2 mA ( or 5.55V, 11.1V min. ) |

| Linear Output Range | 0 - 22.2mA(0-20mA or 4-20mA), 0 - 5.55V ( 0 - 5V, 1 - 5V ), 0 - 11.1 V ( 0 - 10V ) |

| User Interface | Dual 4-digit LED Displays |

|---|---|

| Keypad | 4 keys |

| Programming Port | For automatic setup, calibration and testing |

| Communication Port | RS-232 and RS-485 |

| Control Mode | |

|---|---|

| Output 1 | Reverse ( heating ) or direct ( cooling )action |

| Output 2 | PID cooling control, cooling P band 50 ~ 300% of PB, dead band -36.0 ~ 36.0% of PB |

| ON-OFF | 0.1 - 90.0 ( °F ) hysteresis control ( P band = 0 ) |

| P or PD | 0 - 100.0 % offset adjustment |

| PID | Fuzzy logic modified , Proportional band 0.1 ~ 900.0°F , Integral time 0 - 1000 seconds , Derivative time 0 - 360.0 seconds |

| Cycle Time | 0.1 - 90.0 seconds |

| Manual Control | Heat (MV1) and Cool (MV2) |

| Auto-tuning | Cold start and warm start |

| Failure Mode | Auto-transfer to manual mode while sensor break or A-D converter damage |

| Ramping Control | 0 ~ 900.0°F/minute or 0 ~ 900.0 °F/hour ramp rate |

| Digital Filter | |

|---|---|

| Function | First order |

| Time Constant | 0, 0.2, 0.5, 1, 2, 5, 10, 20, 30, 60 seconds programmable |

| Profiler | |

|---|---|

| Number of profiles | 9 |

| Number of Segment per profile | Profile 1,2,3,4 : 16 Profile 5,6,7 : 32 Profile 8,9 : 64 |

| Event Outputs | 3 |

| Environmental & Physical | |

|---|---|

| Operating Temperature | -10°C ~ 50°C |

| Storage Temperature | -40°C ~ 60°C |

| Humidity | 0 to 90 % RH ( non-condensing ) |

| Altitude | 2000m maximum |

| Pollution | Degree 2 |

| Insulation Resistance | 20 Mohms min. ( at 500 VDC ) |

| Dielectric Strength | 2000 VAC, 50/60 Hz for 1 minute |

| Vibration Resistance | 10 - 55 Hz, 10 m/s² for 2 hours |

| Shock Resistance | 200 m/s² ( 20 g ) |

| Moldings | Flame retardant polycarbonate |

| Dimensions | P41 ---96mm(W) X 96mm(H) X 65mm(D), 53 mm depth behind panel P91 ---48mm(W) X 48mm(H) X 116mm(D), 105 mm depth behind panel |

| Weight | P41 --- 250 grams P91 --- 150 grams |

| Approval Standards | Safety : UL 61010C-1 , CSA C22.2 No. 24-93 , EN61010-1 (IEC1010-1) |

| Protective Class |

|---|

| IP65 front panel with additional option, |

| IP50 front panel without additional option, |

| all indoor use, |

| IP 20 housing and terminals with protective cover. |

| EMC | EN61326 |

|---|

| Documentation | ||

|---|---|---|

| Catalog-Ramp soak controllers | Download | |

| User Manual-P41_P91I | Download | |

| Software&Firmware | ||

|---|---|---|

| Software- BC-Set Pro | Download | |

| Software- BC-Set_V2.0 | Download | |

*BC-SET Pro Compatible models:

Plastic/rubber industry

It is installed on the heating material tube of the injection molding machine to control the temperature of the raw material, effectively control the liquid temperature of the plastic and improve the molding quality of the product.

Installed on the hot runner system for temperature control of runners and gates to stabilize the quality of the plastic.

Temperature control on the mold temperature machine, indirectly adjusting the temperature of the mold by adjusting the temperature of the hot fluid, can improve the production efficiency of the product and reduce the generation of defective products.

Electric heating furnace industry

Vacuum furnace equipment / vacuum melting / vacuum heat treatment

A new algorithm for PID adjustment using fuzzy rules is used to adjust the PID algorithm to eliminate the PID saturation integral phenomenon when the error is large. When the error is small, the improved PID algorithm is used for adjustment and can be automatically adjusted. Learn and memorize some of the characteristics of the controlled object to optimize the effect

Semiconductor industry

The temperature control of the electric heating cloth package is often used for the heating of the exhaust pipe valve parts of the semiconductor factory, the panel factory, or the special steel cylinder.

In the semiconductor temperature process control program, the heating system of the chamber, such as the decane process, the dichloromethane process

Ceramic / kiln / glass industry

Ceramic sintering furnace:

The heating process on the sintering furnace controls the heating rate to obtain a finished product with better quality and stability.

Electric kiln:

Temperature adjustment during kiln firing to obtain a finished product with better quality and stability.

Fiber machinery

Dyeing machine:

control the temperature during dyeing to a suitable range, which in turn reduces chromatic aberration and improves the quality of dyed products.

Fiber dryer:

The temperature during drying is controlled within a suitable range to improve the fiber product.

other

Temperature Controller

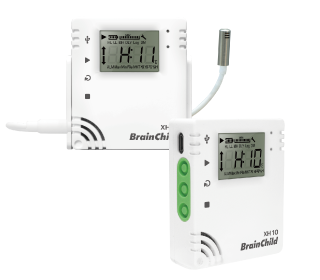

Constant temperature and humidity machine

Heating/cooling air conditioning

Pool/bathroom temperature control facility

| □ | □ | □ | □ | □ | □ | □ | □ |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 1 Power Input | 4: 90 - 264 VAC, 47-63 HZ 5: 11 - 26 VAC or VDC, SELV, Limited Energy |

| 2 Signal Input | 1: Standard Input Input 1-Universal Input Thermocouple: J, K, T, E, B, R, S, N, L, C, P RTD: PT100 DIN, PT100 JIS Voltage: Voltage: 0-60mV 5: 0-10V, 0-1V, 0-5V, 1-5V 6: 0-20/4-20 mA |

| 3 Output 1 | 0: None 1: Relay rated 2A / 240VAC 2: Pulsed voltage to drive SSR, 5V / 30mA 3: Isolated 4 - 20mA / 0 - 20mA 4: Isolated 1 - 5V / 0 - 5V / 0 - 10V 6: Triac output 1A / 240VAC,SSR C: Pulsed Voltage to drive SSR, 14V/40mA |

| 4 Output 2 | 0: None 1: Relay rated 2A/240VAC 2: Pulsed voltage to drive SSR, 5V / 30mA 3: Isolated 4 - 20mA / 0 - 20mA 4: Isolated 1 - 5V / 0 - 5V / 0 - 10V 6: Triac output, 1A / 240VAC, SSR 7: Isolated 20V / 25 mA DC Output Power Supply 8: Isolated 12V / 40 mA DC Output Power Supply 9: Isolated 5V / 80 mA DC Output Power Supply C: Pulsed Voltage to drive SSR, 14V/40mA |

| 5 Output 3 | 0: None 1: Relay rated 2A/240VAC 2: Pulsed voltage to drive SSR, 5V/30mA 6: Triac output 1A / 240VAC,SSR 7: Isolated 20V/25mA transducer power supply 8: Isolated 12V/40mA transducer power supply A: Isolated 5V/80mA transducer power supply C: Pulsed voltage to drive SSR, 14V/40mA |

| 6 Output 4 | 0: None 1: Relay rated 2A/240VAC 2: Pulsed voltage to drive SSR, 5V/30mA 3: Retransmit 4 - 20mA / 0 - 20mA 4: Retransmit 1 - 5V / 0 - 5V/0 - 10V 6: Triac output 1A / 240VAC,SSR 7: Isolated 20V/25mA transducer power supply 8: Isolated 12V/40mA transducer power supply A: Isolated 5V/80mA transducer power supply C: Pulsed voltage to drive SSR, 14V/40mA |

| 7 Output 5 | 0: None 3: Isolated 4 - 20mA / 0 - 20mA 4: Isolated 1 - 5V / 0 - 5V/0 - 10V 7: Isolated 20V/25mA transducer power supply 8: Isolated 12V/40mA transducer power supply A: Isolated 5V/80mA transducer power supply D: Isolated RS-485 interface E: Isolated RS-232 interface |

| 8 Options | 0: Panel mount IP50 standard 1: Panel mount IP65 water resistant rubber installed 2: DIN rail mount with IP50 (for P91 only) 3: DIN rail mount with IP65 (for P91 only) |

.png)