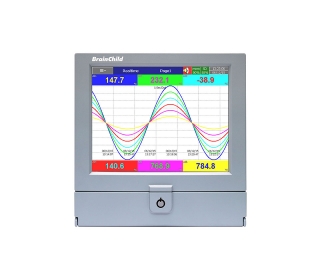

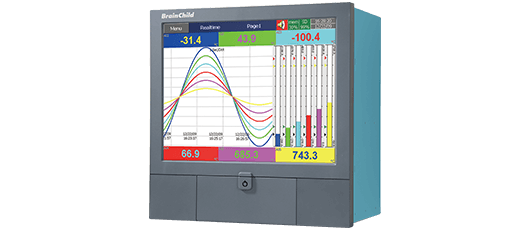

Paperless Videographic Recorder

The new PR series paperless recorders are launched in full product range with outstanding specifications and features. PR series includes a low-cost PR10, a popular PR20 and a high-end PR30. Recorders in 4.3” & 12.1” displays in addition to 5.6”, 100 msec. sampling rate, external channels, batch, custom display, more strict FDA 21 CFR part 11, handwriting messages, SD slot, 2 USBs, pulse input, field calibration, Web Server, email, 19 languages, IP65, and yet in shorter depth 167mm.

Data acquisition, monitoring, recording and controlling can be met in PR20 temperature data logger.

Support Handwriting.

※The stylus is not included.

- Touch Screen, TFT, 65K color

- 100 msec. scan rate

- Internal memory: 256 MB Flash

- CPU: ARM Cortex-A8, 1Ghz

- Standard: Ethernet, SD slot & USB

- Option: RS232/422/485 & Pulse input

- Protection: IP65 front & IP20 rear

- Standards: CE, cULus & RoHS

- Pulse input for flow applications

- Direct printer connectivity

- Webserver & Email directly from Recorder

- Remote IO channels, virtual channels

- Master & slave, modbus RTU and TCP protocols

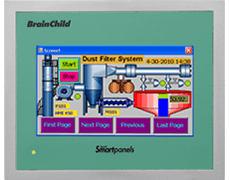

- Custom display pages similar to HMI

- Batch operations, built in security & FDA 21 CFR part 11

- 19 international languages

| Product position | Medium size and powerful one, input numbers up to the highest 24 channels |

| Input numbers | 3, 6, 12, 18, 24channels |

| True universal inputs | Thermocouples: J, K, T, E, B, R, S, N, L, U, P, W5, W3, LR, A1, A2, A3, M RTD: Pt50, Pt100, Pt200, Pt500, Pt1000 (α=0.00385), Pt50, Pt100 (α=0.00391), Ni100, Ni200, Ni500, JPt50, JPt100, JPt200, JPt500, JPt1000 (α=0.003916) Ni1000 (α=0.00617) mA, V, mV |

| The fastest sampling rate | To reach 100 msec / dot, default setting at 1 sec / dot |

| Math, External channels, Batch, Custom display, FDA 21 CFR part 11 |

Math in standard version, others in Plus versions |

| Display | 5.6" TFT wide touch screen |

| Resolution | 640 x 480 |

| MTBF backlight at 25°C | 20,000 hrs |

| Backlight | LED |

| Screen saver, Email | Yes |

| A faster CPU | ARM Cortex-A8, 1Ghz |

| Internal flash memory | 256 MB |

| RAM | 256 MB |

| Ethernet | Modbus TCP/IP |

| RS-232/422/485 | Optional RS-232 or RS-422/485 Modbus RTU |

| SD card slot, USB host x 2 | Standard, one USB in the front, another USB in the back |

| Pulse input | Optional DI card offering either logic or high frequency pulse counter |

| Process control | PID, Ramp& dwell |

| START / STOP key | To start / stop record and to turn off the display only, not recorder itself so that a quick start possible |

| Calibration correction | On-site calibration possible, or using handy features of Offset and Gain for correction |

| Multilingual | Convenient for local users by offering 19 languages including English, Japanese, Danish, Italian, Polish, Russian, Dutch, Korean, Thai, Turkish, Portuguese, Chinese (simplied, traditional), French, German, Spanish, Swedish, Brazil Portuguese, Czech, other languages negotiable |

| PC software historical viewer+ configuration | Standard |

| Extensive software data acquisition studio | Optional real-time monitoring |

| Power supply | 90-250VAC or 11-36VDC |

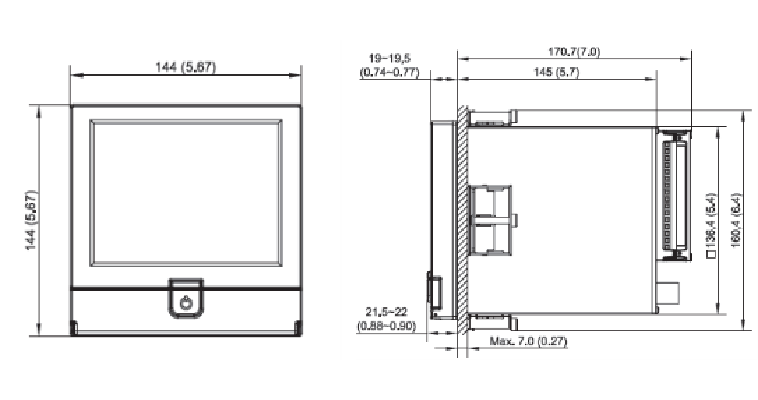

| Outer dimensions (W x H x L mm) | 144 x 144 x189 |

| Shorter mounting depth (mm) | 171 |

| DIN panel cutout (W x H mm) | 137 x 137 |

| Protection | IP65 front, IP20 rear |

| Operating temperature | 0°C to 50°C |

| Storage temperature | -30°C to 70°C |

| Safety standards | CE, cULus, RoHS |

| Documentation | ||

|---|---|---|

| Catalog-Paperless Recorder | Download | |

| User Manual-PR User Manual-Full Version_UMFPR01K | Download | |

| User Manual-Process Control Card PC201 User Guide_UMPC201 | Download | |

| User Manual-Communication Manual_UMPRCM01C | Download | |

| Software&Firmware | ||

|---|---|---|

| Software- Historical Viewer_V4.73(2501) | Download | |

| Software- Data Acquisition Studio (DAQ)_V2.73(2501)※1-hour trial only | Download | |

| Firmware- PR PV210_V1.72(2501) | Download | |

| Software- Data Acquisition Studio (DAQ)_V2.51※1-hour trial only (For PR with 1.42 and earlier version) | Download | |

| Software- Historical Viewer_V4.51(2312) (For PR with 1.42 and earlier version) | Download | |

Firmware V1.7(2501) Release note (Jan, 2025):

- Bug fixed: DO cards will work abnormally after loading config data coming from the old version.

- Bug fixed: If the network is interrupted unexpectedly during ethernet dumping, PR will stop responding after the connection is restored.

- Bug fixed: The system time behaves abnormally about 50 days after booting.

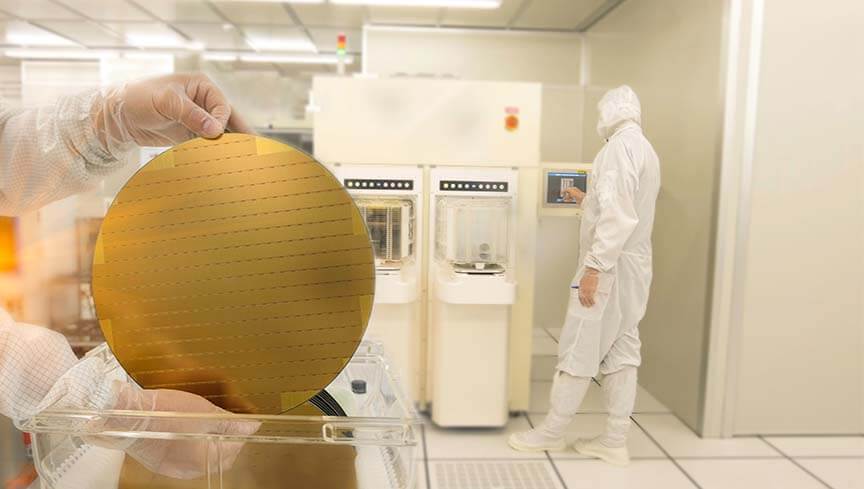

Semiconductor industry

Control of furnace temperature for temperature process in semiconductor temperature process control

Ceramic / kiln / glass industry

Temperature record as a heating process in a ceramic sintering furnace

other Applications

Water treatment PH/conductivity record

Food sterilization process record

Exhaust gas treatment system record

Quality assurance test standard

Medical mechanical water system

It is used for environmental parameter monitoring and recording, and can set numerical abnormal alarm. It can choose paperless recorder to realize paperless recording mode, and can also record key parameters in real time with paper recorder.

Beer brewing system

It can be used for environmental parameter monitoring and recording, and can set numerical abnormal alarm. It can choose paperless recorder to realize paperless recording mode, and can also record key parameters in real time with paper recorder.

.png)