FAQ

A73Yes, HMI can support barcode reader via USB port.

A74Our HMI can communicate with temperature controllers with Modbus RTU or TCP/IP communications with the HMI configured as the Master.

A75WinCE is mature and stable system with many ready-made tool that reduced development time for Panel Studio HMI editing software and is easy to implement 3rd party software.

A76Sound input can work with microphone, for example to leave a message to the next shift worker in factory. Sound output works with speaker, for example to play the alarm warning.

A77Yes, it is easy because of same dimensions, panel cutouts, use of Symbol Factory and options of stainless steel front bezels.

A78It was developed by taking advantages of Siemens’ and AB’s software. So, it is quite powerful and handy. Please refer details on comparative charts.

A79Yes, software Panel Studio does support multilingual in two ways. To display multilingual on HMI, specific languages can be keyed in via keyboard. To read the software itself, the user can also choose any one of 18 available languages.

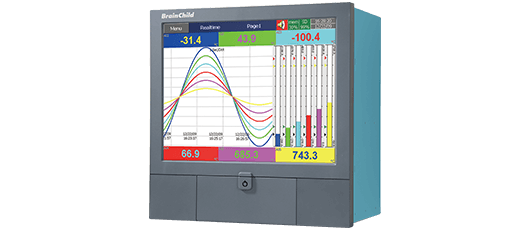

A80Yes, our HMI supports data acquisition function. The user can read real-time and historical data and trend on HMI. Also, it is possible to search and export data to Excel format as well as use the included PC based Historical Viewer software to view exported data..

A81Yes, by using the USB port on the HMI and a specific USB to COM converter US-101-485 supplied by us, the user may a 3rd COM port.

A82Yes, it can be done by configuring one HMI as Modbus RTU Master and another as Modbus RTU Slave.

A83It depends on Transceivers and Protocol used. In case if low power Transceivers are used, it is possible to communicate with maximum of 247 devices on Modbus protocol. In case of high power Transceivers are used, it can drive till 32 devices.

A84You can use commercially off the shelf USB hub available and then connect your devices to hub.

.png)